Balsam poplar wood s short and fine fibers are features that allow it to go into the making of paper products including tissues. If you don t know how to draw a step 2 cut the tree out and make a second copy.

Cut the tree out first.

Tree used for making paper. One of the people credited with the development of papermaking in china was cai lun a eunuch in the court of the han dynasty. It is estimated that 24 trees to make 1 ton of standard office paper. Other hardwoods applied in this industry are oaks aspen birch and maples.

Step 1 fold brown paper in half and draw half of a bare tree along the fold. So it would take about 8 of these trees to produce between 1 000 and 2 000 pounds of paper since a typical 500 sheet packet of the paper weighs 5 pounds that s 10 000 to 20 000 sheets per tree which doesn t sound all that bad. A tree that requires full sun to develop balsam poplar frequently grows in pure stands reports the national audubon society field guide to trees.

In general the softwoods e g pines firs and spruces yield long and strong fibers that impart strength to paper and are used for boxes and packaging. Different kinds of trees produce a different texture of paper. However the strength and quality of fiber and other factors that can complicate the pulping process varies among tree species.

Major tree types in the softwoods category are spruce pine fir larch and hemlock. Be sure to include the roots trunk and branches. Find a sheet of heavy brown paper such as cardstock and fold it in half.

Draw half of a bare tree shape along the fold. Today s paper is made mostly from two different products. Fold a second sheet.

Eucalyptus is a hardwood that has largely been used for paper production. History of paper making. The tree also called black cottonwood is a hardwood species that grows across most of canada and into northern new england and the great lake states.

Do not include any leaves 1 x research source make sure that the roots are flat and straight along the bottom edge. The fiber from nearly any plant or tree can be used for paper. Choosing the right kind of tree to make paper.

Connect with an age old process and the life cycle of plants to make fragrant textured paper. It was also the beginning of production for newsprint. Historical evidence indicates that the chinese were the first society to develop a method to make pulp.

See the photos on this page for step by step guidance in the papermaking process. Archaeologists indicate that the most ancient pieces of paper ever collected were from china from the 2 nd century bce. This new process ended 2 000 years of making paper from rags.

Pulpwood logs and recycled materials from paper.

In some cases multiple materials are used to construct a chair. Plus it is usually cheaper.

Types Of Chairs Material And Design Used In Making Chairs

An important part of selecting the right office chair is selecting one constructed of a material with which you can feel comfortable.

Materials used in chairs. Fabric is a softer and more practical material used for the upholstery especially for chairs. Unlike other wood cherry is more expensive and is seen as more rare than its counterparts. From fabric to mesh to genuine leather and faux leather each offer their own unique benefits and drawbacks that we ll highlight below to help you make your chair selection.

The types of material for desk chairs office chairs are available with seats and back rests constructed from a large variety of materials including leather faux leather mesh vinyl wood fabric and plastic. Maintenance involves the occasional waxing. Plastic laminate widely used for table and other tops is obtainable in various colours and designs and in photographically reproduced natural wood grain.

This built to last wood material mostly seen used on antique furniture such as carved chairs and shaker style tables and cabinets comes in a lush reddish brown natural tone and can be easily shaped. If you are looking for a store that can offer you all of the above mentioned furniture materials try visiting furniture in fashion website. For example for their famous moulded shell chairs charles and ray eames used fibreglass reinforced polyester which was originally designed for protective helmets.

Below mentioned are some of the different types of materials used for making furniture. Fibreglass is one of the newer materials used for furniture especially for outdoor chairs. Along with it being waterproof and resistant to moulds it is understandable why this material has become a popular choice for furniture these days.

Chairs can be made from wood metal or other strong materials like stone or acrylic. It is extremely durable fade resistant and strong. Plastic plastic is a versatile material that is light in weight it can be reformed into various shapes easily and they are cheap to manufacture.

For example the legs and frame may be made from metal and the seat and back may be made from plastic. Choosing an office chair is hard enough as is let alone choosing the type of chair material. Steel especially tubular steel became popular as a furniture making material after the popularity of the wassily chair also known as the model b3 chair which was designed by marcel breuer in 1925 1926 while he was the head of the cabinet making workshop at the bauhaus in dessau germany.

First of all this is one of the biggest stores in the uk so the selection they offer is worth checking out. An entirely new formal idiom was developed and occupied itself with exploring the possibilities of the material. Its advantages are that it resists all liquid stains is largely heat proof against burn marks is mark free and is easily wiped clean.

Although wood has always been regarded as the traditional material for furniture making several other materials are now used either entirely replacing wood or combined with it. Types of materials used for making furniture.

Making the meat sauce part two. It is the trickiest step in making a bed but is also the part which will make your bed look neatest.

How To Build A Longbow 13 Steps With Pictures Wikihow

These step by step tips will teach you how to make fried eggs whether you like them sunny side up or over easy.

How to make a long bow step by step. Pour 5 cups 1 2 l of water into the pot. In this video tutorial you will see how to make a flower out of paper. Mix it around for a moment and bring to a light boil.

A step by step guide follow these simple tips and. If you already have a domain name and hosting you can skip this part since we re using bluehost and have been for a long while we ve negotiated a special discount for all our readers 67 off. Make the sushi roll.

How to draw 3d step by step. This is the last step in this sushi recipe. Step 2 on the chosen fire board carve it down so that it is flat to the ground so that it s not moving and sliding everywhere.

A film may develop on the top of the water as the mixture boils. Many of these colors from paper to decorate your room for a holiday wedding. Step 1 with the chosen stick drill that you will be using sand or scrape away any rough areas that would otherwise cut the hands off you.

You can also make it a point to get to know your own body in a sexual way. Choose a blog hosting plan. Add the water and bring the mixture to a boil.

How to deep fry fish and chips. Watch out for splatters. Then put the chosen ingredients on the layer of rice.

Any age children from toddlers to older children. Let the sauce simmer for at least a half hour while you do the rest of the prep work. Lower the heat to a simmer and cover.

Accepting your body is key to a happy self and the first step to better sex life. Don t just stuff it in though. Now open both cans of tomatoes and dump them in.

The term hospital corner refers to a specific method of folding the end of the top sheet tightly under the mattress. Once you have the layer of rice put a bit of mild sauce or mayonnaise across the width and more or less in the lower third of the surface covered with rice this step is optional. Try looking at yourself in the mirror and make it a point to find a new positive about yourself each day.

To make a hospital corner tuck the end of the top sheet between the mattress and box springs at the foot of the bed. Drawing of paints and pencil. Raise the heat to medium high and allow the mixture to come to a boil which may take approximately 10 minutes.

The technician puts the lens bank into a grinding machine and grinds it into a shape that matches your prescription even closer. The lens prescription is verified from the lab.

Then the back side of your lenses is cut according to the parameters of your prescription.

How eyeglass lenses are made. Quartz and beryl lenses were replaced by glass lenses because of the increasing demand for eyeglasses. They were made from a transparent quartz and beryl lens. The process is slightly different for semi finished lenses made of glass.

The optical center of the lens is dotted. First natural materials such as quartz potassium carbonate soda and oxide are melted at 1400 to 1500 c to form a glass mixture. While the same process is used to produce lenses for telescopes microscopes binoculars cameras and various projectors such lenses are usually larger and thicker and require greater precision and power.

Eyeglass lenses are first made by a lab technician reviewing your prescription and taking a lens bank a curved glass or plastic disc that is the basis of the lens that closest matches your prescription. After your eye prescription order is sent on to the laboratory the clerk in the stock picking department chooses the appropriate semi finished lens blanks. Your glasses are an extension of your being.

The lab technician chooses a blank closest to the prescription and places it into a machine where it s ground to a curve matching the prescription. The lenses are then made with the help of machines. Plastic as well as glass lenses are produced by successive stages of fine grinding polishing and shaping.

Specialized machines then cut and bevel the lenses down to the right shape for the frame and the wearer s prescription. So many canadians rely on modern optometry technology to allow them to live a normal and functioning life. Following this invention alessandro di spina made eyewear available to the general populace.

Most glasses start off with blanks or round pieces pre made by optical labs with varying front curves and different thicknesses based on how much help your eyes need. So how are lenses actually made. The type of lens selected is unique for each order prescription.

Understanding exactly how eyeglass lenses are made is a little confusing. How eyeglasses lenses are made eyeglass and sunglass lenses are shaped from plastic disks. So let s review what progressive lenses actually are and how they re made.

A laser marking in this process will make sure the lenses are molded to your measurements. This is how we line up the cylinder on correct axis. Then this is pressed to form a round glass block that is one to three centimeters thick called a pressing.

Wood shingles are sawed from red cedar or pine. Typically coated steel stainless steel or aluminum roofs are usually seen on commercial properties although you will see copper zinc alloys or.

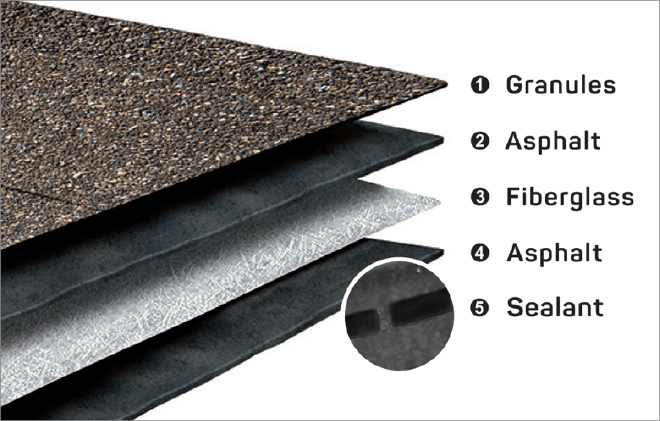

Asphalt Shingles What Are They Made Of

This powder is then mixed with the asphalt to create a filled coating.

What are roof shingles made of. Shingles made with asphalt as the main ingredient are the most popular shingles sold in the u s. Single ply roofing is a popular option for commercial buildings and can be used on any slope of roof. What materials are used to make different types of roof shingles.

Roof shingles consist of a series of individual overlapping components that when laid together in rows or courses starting at the bottom edge of a roof form a barrier designed to repel water snow and ice. Asphalt roofing shingles are reinforced with a thin fiberglass mat made from glass fibers of specific length and diameter bound together with the help of stable resins and binders. Roof shingles may deteriorate faster and need to repel more water than wall shingles.

Most asphalt shingles are made from limestone that has been crushed into a very fine powder. They are a very common roofing material in the united states. Roof shingles are installed in such a fashion that each seam or joint is overlapped by a shingle further up the roof.

Roofing shingles are made from several types of materials. Asphalt is the most common type of material. Ceramic roof tiles which still dominate in europe and some parts of asia are still usually called tiles.

Thermoset membranes are made with layers of synthetic rubber polymers such as epdm cspe and neoprene. Today and so the asphalt used at these roofing facilities is processed to meet the stringent quality requirements needed to create strong yet flexible shingles. Standard shingles made with asphalt can be either conventional 3 tab roof shingles or more decorative architectural shingles.

The fiberglass is wound into large rolls at the fiberglass mill which are then unwound at the start of the roofing shingle manufacturing process. Shingles are held by the roof rafters and are made of various materials such as wood slate flagstone metal plastic and composite materials such as fibre cement and asphalt shingles. Wood shingles offer a rustic look and are a natural product usually made from cedar redwood and southern pine.

Modern shingles are cut from new growth trees and must be treated with chemical preservatives to make them last as well as earlier versions that were cut from old growth trees. There are a few different materials that are effectively used for shingles. Next huge mats of fiberglass are fed into a coater where the filled coating is applied.

If you live in a fire prone area look for class a fire rated wood roofing products that include shingles treated with a fire resistant coating. There are two main types of single ply roofing. Wood is recyclable into wood chips mulch or compost.

Wood has an insulation value twice that of asphalt shingles but your home s insulation levels are far more important than the r value of the roofing many shakes and shingles are made from salvaged trees those that have fallen over from age or toppled by storm. Metal is also used as for roofs.