International paper is excited to release the all new 21st edition of the pocket pal the authoritative introduction to the graphic arts. It s called the pocket pal and for the last 85 years international paper s been tucking it into the grateful hands of designers printers and everybody else who really wants to know the facts.

Pocket Pal A Graphic Arts Production Handbook By Michael H Bruno

Order 1 9.

International paper pocket pal. International paper 1801 n shelby oaks drive ste. Your contact information is confidential and will not be shared. 12 memphis tn 38134 usa phone.

Order 10 or more. History and evolution of printing. Pocket pal 21st edition.

But don t let the age fool you. Privacy policy legal statement disclaimer this site is best viewed with internet explorer 5 5 or greater. For over 85 years this pocket sized handbook has been acclaimed by industry experts as the go to print reference guide for students designers printers publishers and virtually anyone in visual communications.

We ve also taken into account the international appeal of the publication. 20th edition fire sale. 2008 2021 international paper company.

The 21st edition of pocket pal includes the following. Required email address. We have used metric numbers and have defined every acronym in this clear concise 256 page book notes romano.

The 21st edition of pocket pal covers them concisely.

When pressing is used the excess water is removed by force. Diluting the paper fibres this way allows us to make thin uniform paper.

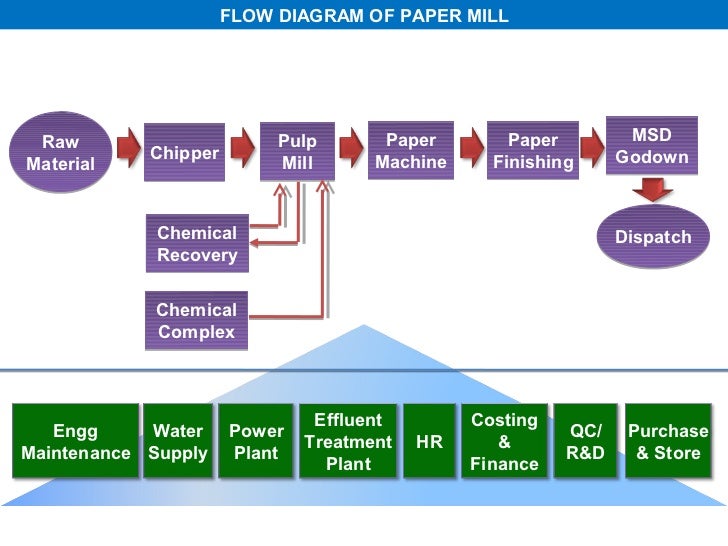

Chapter 72 Pulp And Paper Industry

The final stage of the paper making process is drying which is accomplished with time and pressing of the paper.

How to make paper industrial process. Paper is made through the following processes. Although paper can be recycled it has to be put through the same process as making paper from wood. Once forced out an absorbent material is used to collect the water.

The old paper also has to have the ink removed and this chemical process can weaken the fibers even more. Our paper machines remove water from the fibre solution. The exact method for drying depends on the overall process used to make the paper.

1 pulping procedure will be done to separate and clean the fibers 2 refining procedure will be followed after pulping processes 3 dilution process to form a thin fiber mixture. The process causes the wood fibers to become weaker. At the start of the papermaking process the solution comprises of roughly 1 fibre and 99 water.

At the wet end of the paper machine sits the headbox which distributes a uniform jet of watery stock.

A video showing how the tetra pak factory in sweden manufactures paper cartons used for packaging milk and fruit juices. The containerboard combining process which glues one or more sheets of fluted corrugating medium to one or more flat facings of linerboard.

Corrugated Box And Folding Carton Manufacturing Process With Individual Machine Hebei Shengli Carton Machinery

Pulp and paper manufacturing process in the paper industry paper plays a key role in our daily life and papers have been used for many years from now.

Paper carton manufacturing process. It is now very common for these liners to also be made up of a considerable proportion of recycled content sourced from old cardboard or other sources of second hand paper. This includes paper board making the first step in the carton manufacturing process is the making of the paperboards. According to which model you decide on you can produce a huge number of egg crates each hour so you won t must do any of the work yourself when you spend money on an.

The softened wooden chips are then made in to a pulp form. In this process wooden chips are first softened by adding chemicals. Kraft paper involves pulping wood chips and then feeding the resulting paper substance through massive steam rollers that remove the water.

The paper egg carton manufacturing process is eco friendly and it is good for the environment because it uses waste paper pulp to create the cartons with egg carton machine. The manufacture of corrugated packaging can be roughly classified into two processes. You will need to gather good quality craft paper from the suppliers.

Process varies among tree species. Corrugating is also done in a machine that utilizes heavy rollers. The first process in the manufacturing of cardboard box including process the raw materials.

Packaging box raw material. However for top quality boxes virgin kraft is still used. The main raw material of the packaging box manufacturing business is craft paper.

In general the softwoods e g pines firs and spruces yield long and strong fibers that impart strength to paper and are used for boxes and packaging. A cardboard box is basically made up of a flute made up of recycled paper sandwiched between two liners. Papers are made with the pulp of the woods which is an eco friendly product.

Corrugated cardboard manufacture includes two key steps. The preferred tree for the kraft paper is a pine tree. Once it is harvested the lot goes through a sulfate process and then they are broken down to a pulp.

Making kraft paper and corrugating the cardboard. The qualities of craft papers actually determine the quality of your packaging boxes. It starts by pulping wood chips using a kraft process.

Other raw materials that are required glue and stitching wire. Hardwoods on the other hand generally have shorter fibers and therefore produce a weaker paper but one that is smoother more opaque and better suited. In carton manufacturing a series of sequential process is being carried out.

And the box manufacturing process which is used to assemble the corrugated sheets into boxes.

How to use this guide if you want to learn just about everything about process flowcharts just read through the whole thing we ve got you covered. Use a flowchart when you want to explain the steps in a process with someone else such as someone that you re training in for a job.

All About Paper Making Process

Otherwise strip it off with a knife held flat while holding the bark strip on your towel covered thigh.

Paper making process flowchart. At the wet end of the paper machine sits the headbox which distributes a uniform jet of. They often use arrows to illustrate how one step leads to another. Modern papermaking methods although significantly more complicated than the older ways are developmental improvements rather than entirely new methods of making paper.

What is the flowchart software you used for creating this flowchart. The process of making paper is based on the fact that wet cellulose fibers bind together when dried under restraint. A process flowchart sample is a graphical representation of the steps in the process of achieving a desired result.

Flowchart for papermaking from plant fibers. In the paper making process the dilute stock passes through a headbox that distributes the fiber slurry uniformly over the width of the paper sheet to be formed. Strip the bark peeling the new bark off of the woody core.

Diluting the paper fibres this way allows us to make thin uniform paper. Flowcharts are often used for training documenting and planning. Flowcharts solution offers wide set of useful drawing tools collection of samples ready to use template and 2 libraries with predesigned vector elements which will help facilitate drawing process and designing professional looking process flow chart process flow scheme process block diagram etc.

Floor chart of paper making process. A process flowchart is a graphical representation of a business process through a flowchart. Flowcharts shows the workflow through the use of boxes connected by arrows having a single direction to indicate the order of the process which comes first and what is next.

Adding more colors to this setup will make it more appealing. The wet end of the paper forming machine. Process flow chart gives details of a process by listing the main steps and.

Peelpour off boiling water and replace with cold. It s used as a means of getting a top down understanding of how a process works what steps it consists of what events change outcomes and so on. Thanks 29 september 2016.

Essential to the process are the fibers which are never totally destroyed and when mixed and softened form an interlaced pattern within the paper itself. They can also be useful for decision making. Hello i would like to ask whether there are more related things to do as a chemical process engineer in a paper making facility than in a paper processing mill.

If possible also peel off the outer bark at this time. At the start of the papermaking process the solution comprises of roughly 1 fibre and 99 water. The web of fiber that will make the new paper sheet is formed on a continuously moving.

Our paper machines remove water from the fibre solution.