This easy process involves melting pre made blocks of soap and adding your own fragrance. These chemically react together in what is called saponification and produce the soap along with glycerin as a.

Free Beginner S Guide To Soapmaking Cold Process Soap Queen

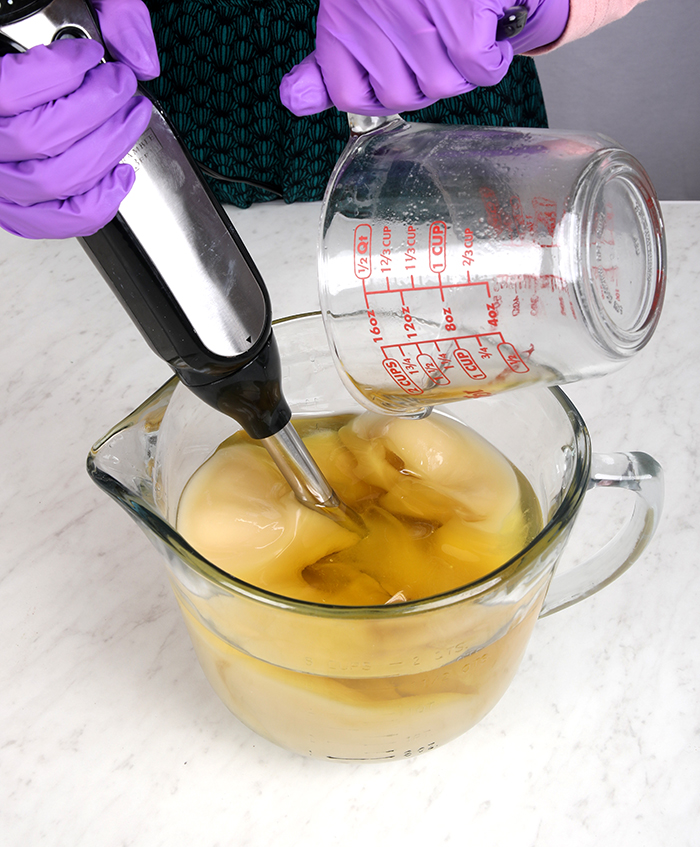

Cold process soap is made from oils lye and water.

Process of making soap. Soap by definition is fat or oil mixed with an alkali. The hot process and rebatching are more advanced methods. Soap making relies on the process of splitting fat into fatty acids and glycerin.

When these ingredients are combined at the right temperature they harden into soap in a process called saponification. The oil is from an animal or plant while the alkali is a chemical called lye. Go to your local craft store and grocery store to purchase the ingredients listed.

The kettle process and the continuous process. Making soap at home requires two types of ingredients an acid and a base. The soap manufacturing process can be separated into two main groups.

The kettle process produces soap in one batch at a time while the continuous process makes soap continuously. There are four basic methods for making soap at home. Two of the most popular methods are the melt and pour and cold process.

In bar soapmaking the lye is sodium hydroxide.

The Pros And Cons Of Soap Making Methods Brambleberry

How Soap Is Made Material Manufacture Making Used Processing Components Procedure Steps